Engineering Services

Onward Resources’ licensed engineering team are industry experts in the safe and efficient movement of both gas and liquids. Having worked to deliver many of the largest oil and gas projects of the last decade, they have the proven skills, capabilities and dedication needed to deliver mission-critical projects with the highest of standards.

The Onward Resources Difference

Multidiscipline In-House Engineering

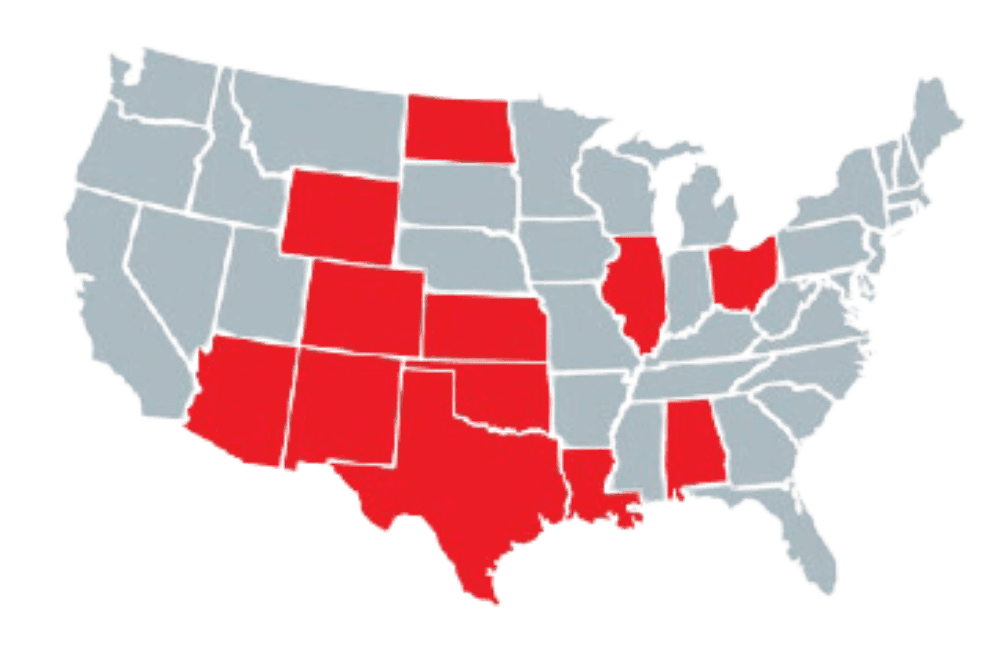

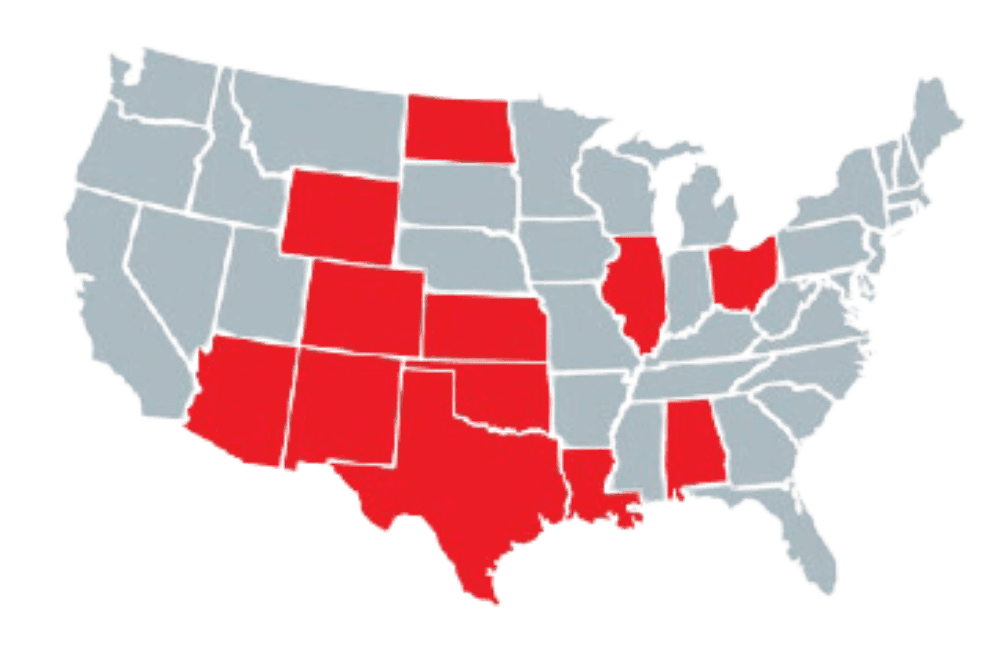

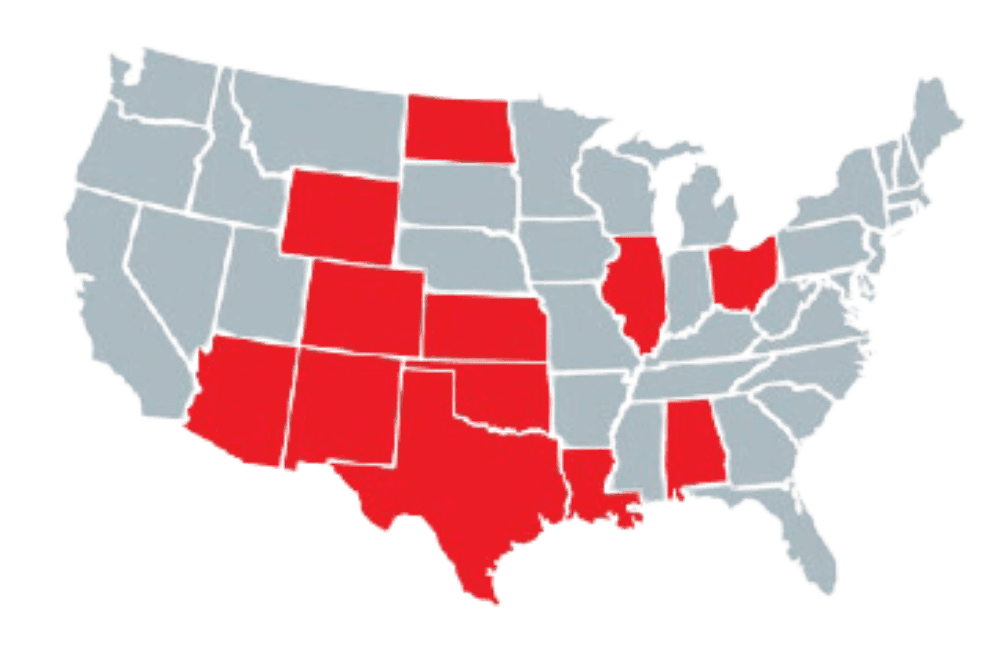

Professional engineers in majority of US states

Experienced Project Managers

Experienced Project Managers

Experience design and drafting groups

Experience design and drafting groups

Disciplines

Project Management

Process

Civil and Structural

Materials

Facilities

Mechanical

Electrical

Automation

Contruction Management

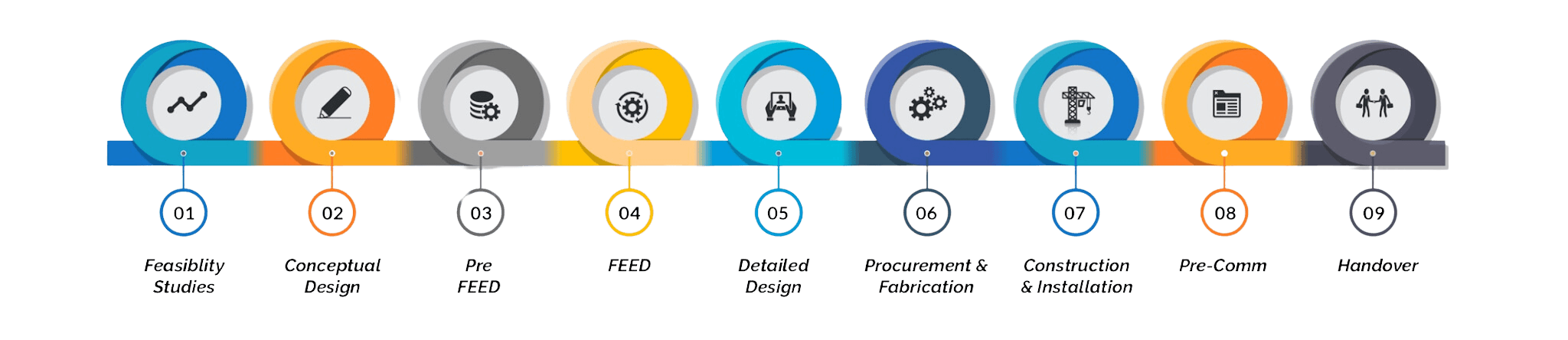

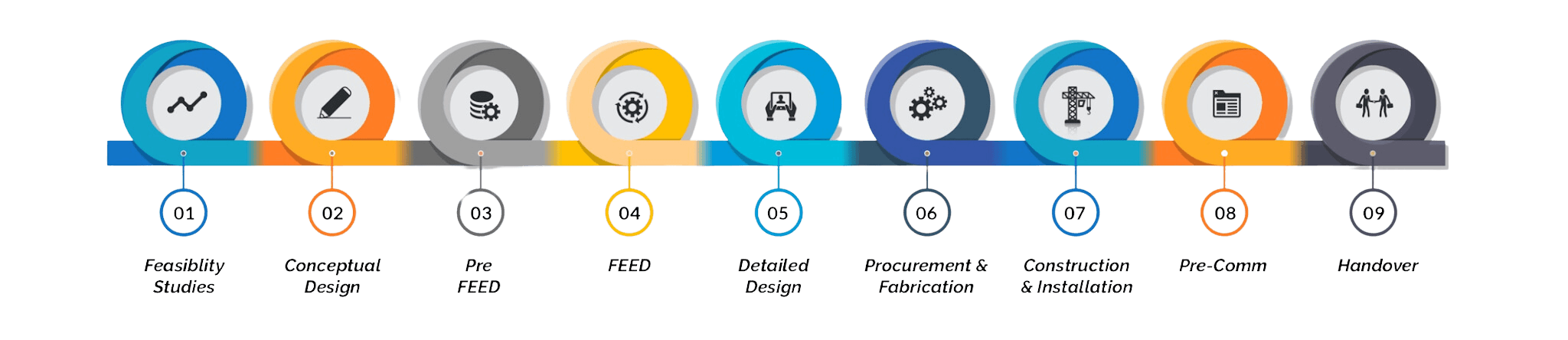

Project Lifecycle Support

Our Engineering Services

At Onward Resources, we provide comprehensive engineering solutions across the oil and gas midstream sector. Our expertise includes:

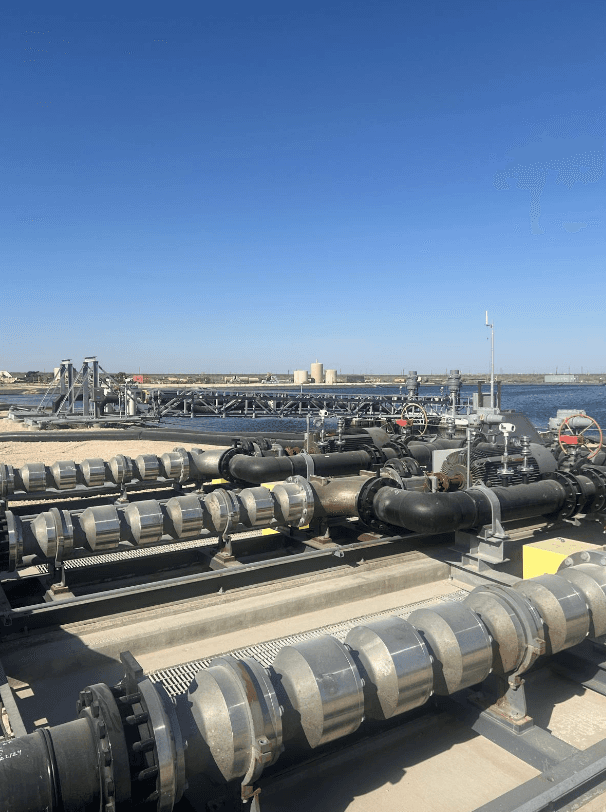

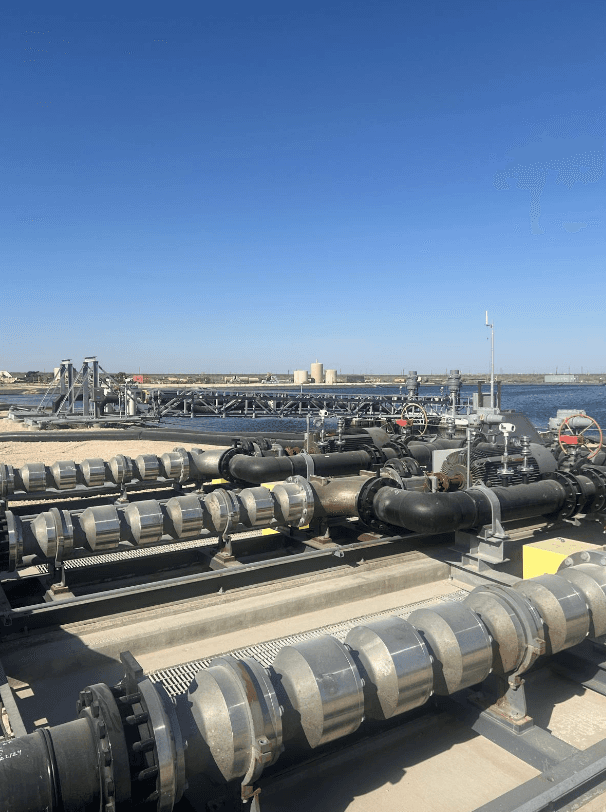

Pipeline Systems

Gathering and Transmissions. Design, construction, and optimization of pipeline infrastructure for safe and efficient transport of oil and gas.

Pipeline Systems

Gathering and Transmissions. Design, construction, and optimization of pipeline infrastructure for safe and efficient transport of oil and gas.

Pipeline Systems

Gathering and Transmissions. Design, construction, and optimization of pipeline infrastructure for safe and efficient transport of oil and gas.

Pipeline Systems

Gathering and Transmissions. Design, construction, and optimization of pipeline infrastructure for safe and efficient transport of oil and gas.

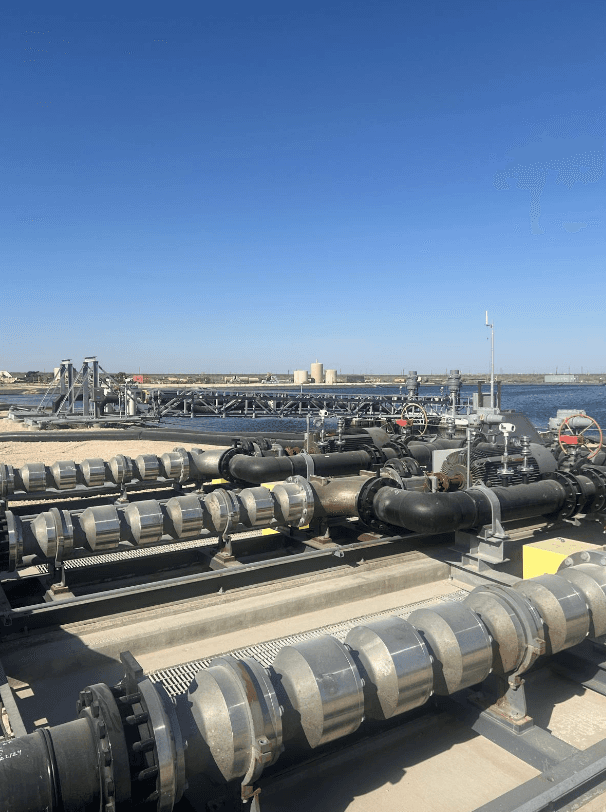

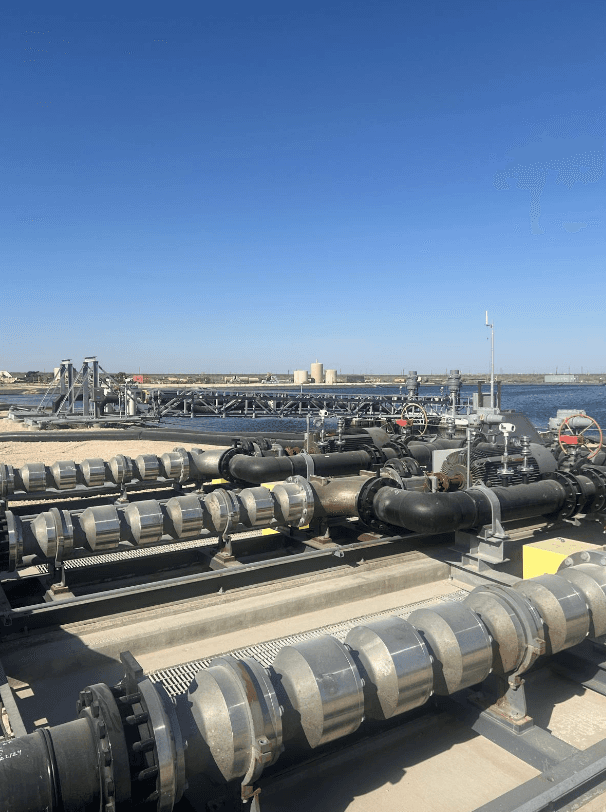

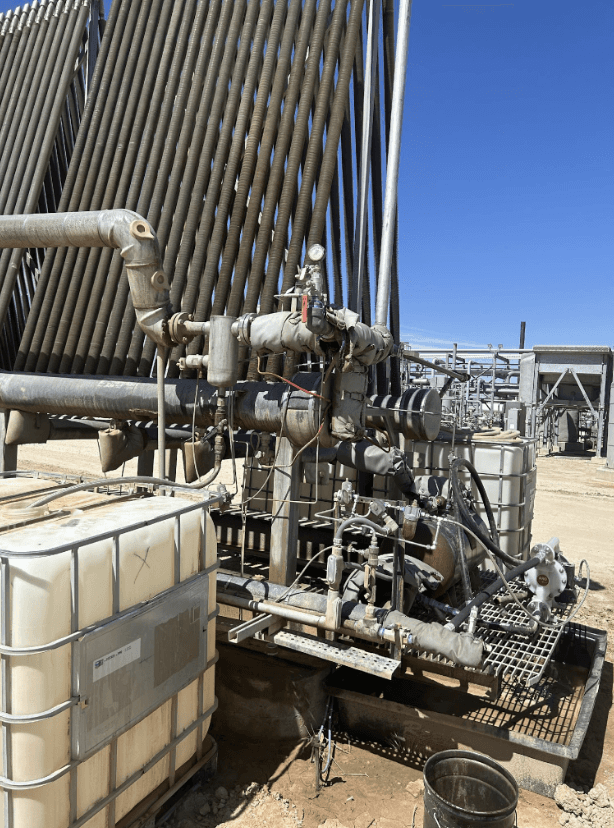

Pump and Compressor Stations

Engineering and installation of pump and compressor stations, ensuring optimal flow and pressure for pipeline systems.

Pump and Compressor Stations

Engineering and installation of pump and compressor stations, ensuring optimal flow and pressure for pipeline systems.

Pump and Compressor Stations

Engineering and installation of pump and compressor stations, ensuring optimal flow and pressure for pipeline systems.

Pump and Compressor Stations

Engineering and installation of pump and compressor stations, ensuring optimal flow and pressure for pipeline systems.

Storage Systems and Terminals

Design and management of storage facilities for oil, gas, and related products, including terminals that facilitate distribution.

Storage Systems and Terminals

Design and management of storage facilities for oil, gas, and related products, including terminals that facilitate distribution.

Storage Systems and Terminals

Design and management of storage facilities for oil, gas, and related products, including terminals that facilitate distribution.

Storage Systems and Terminals

Design and management of storage facilities for oil, gas, and related products, including terminals that facilitate distribution.

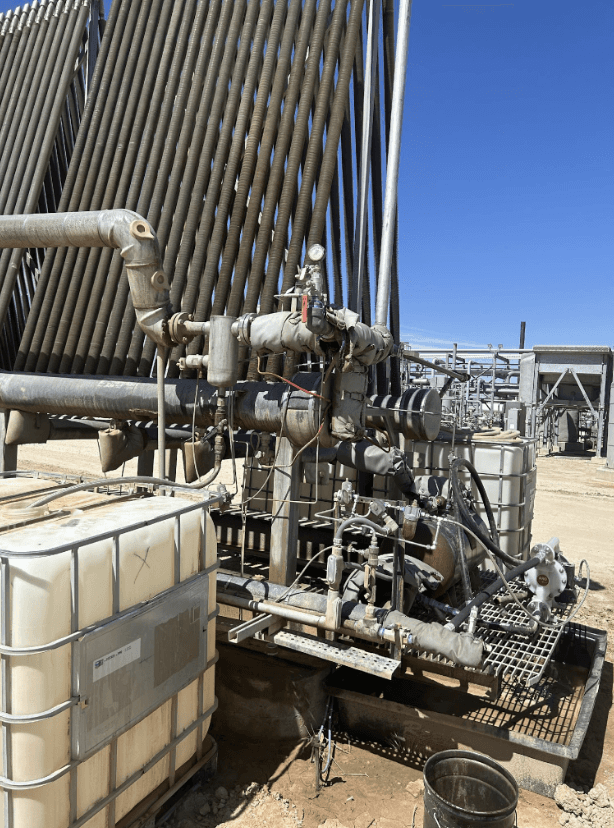

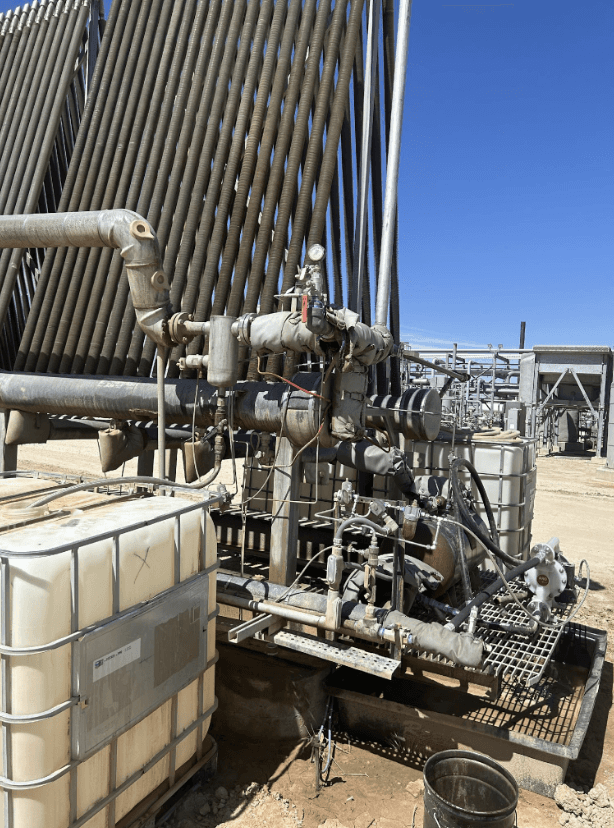

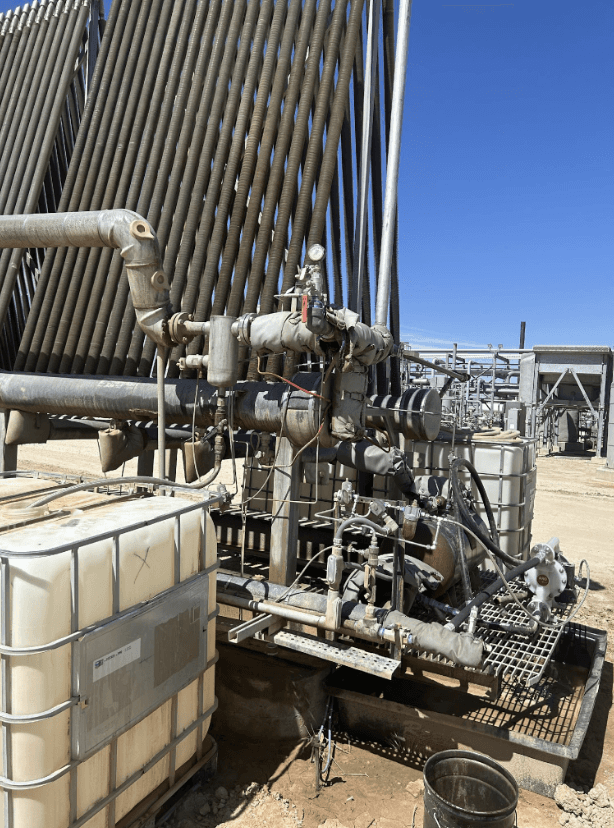

Metering and Regulation

Solutions for accurate metering and regulation of oil and gas flow, ensuring compliance and operational efficiency.

Metering and Regulation

Solutions for accurate metering and regulation of oil and gas flow, ensuring compliance and operational efficiency.

Metering and Regulation

Solutions for accurate metering and regulation of oil and gas flow, ensuring compliance and operational efficiency.

Metering and Regulation

Solutions for accurate metering and regulation of oil and gas flow, ensuring compliance and operational efficiency.

Oil and Gas Processing Plants

Engineering of processing plants that refine, separate, and prepare oil and gas for market distribution.

Oil and Gas Processing Plants

Engineering of processing plants that refine, separate, and prepare oil and gas for market distribution.

Oil and Gas Processing Plants

Engineering of processing plants that refine, separate, and prepare oil and gas for market distribution.

Oil and Gas Processing Plants

Engineering of processing plants that refine, separate, and prepare oil and gas for market distribution.

Carbon Capture Solutions

Cutting-edge technology to capture and store carbon emissions, supporting sustainability and environmental protection initiatives.

Carbon Capture Solutions

Cutting-edge technology to capture and store carbon emissions, supporting sustainability and environmental protection initiatives.

Carbon Capture Solutions

Cutting-edge technology to capture and store carbon emissions, supporting sustainability and environmental protection initiatives.

Carbon Capture Solutions

Cutting-edge technology to capture and store carbon emissions, supporting sustainability and environmental protection initiatives.

Launchers and Receivers

Specialized systems for pipeline maintenance, facilitating pigging operations to clean and inspect pipelines.

Launchers and Receivers

Specialized systems for pipeline maintenance, facilitating pigging operations to clean and inspect pipelines.

Launchers and Receivers

Specialized systems for pipeline maintenance, facilitating pigging operations to clean and inspect pipelines.

Launchers and Receivers

Specialized systems for pipeline maintenance, facilitating pigging operations to clean and inspect pipelines.

Main Line Valves (MLVs) and Valve Settings

Design and installation of mainline valves, offering precise control and safety in pipeline operations.

Main Line Valves (MLVs) and Valve Settings

Design and installation of mainline valves, offering precise control and safety in pipeline operations.

Main Line Valves (MLVs) and Valve Settings

Design and installation of mainline valves, offering precise control and safety in pipeline operations.

Main Line Valves (MLVs) and Valve Settings

Design and installation of mainline valves, offering precise control and safety in pipeline operations.

Owner’s Engineering (OE)

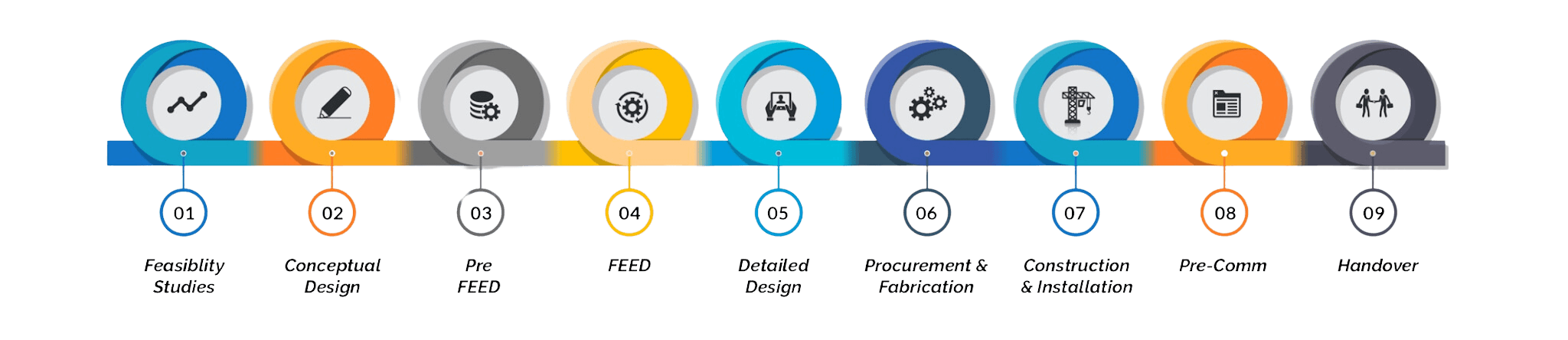

Onward Engineering will support the client by providing a specialized team or individual engineers, either in-house or from a third-party consultancy, to act as their technical representative during the planning, design, procurement, construction, and commissioning phases of a project. This team provides independent oversight and technical expertise to ensure that the project is designed, built, and operated in accordance with the owner’s objectives, regulatory requirements, and best practices.

Onward Engineering will support the client by providing a specialized team or individual engineers, either in-house or from a third-party consultancy, to act as their technical representative during the planning, design, procurement, construction, and commissioning phases of a project. This team provides independent oversight and technical expertise to ensure that the project is designed, built, and operated in accordance with the owner’s objectives, regulatory requirements, and best practices.

Key Roles of an Owner’s Engineer:

Project Management and Coordination

Ensures all aspects of the project are moving in alignment with the owner's goals, and coordinates between contractors, designers, and stakeholders.

Project Management and Coordination

Ensures all aspects of the project are moving in alignment with the owner's goals, and coordinates between contractors, designers, and stakeholders.

Project Management and Coordination

Ensures all aspects of the project are moving in alignment with the owner's goals, and coordinates between contractors, designers, and stakeholders.

Project Management and Coordination

Ensures all aspects of the project are moving in alignment with the owner's goals, and coordinates between contractors, designers, and stakeholders.

Technical Review and Assurance

Review engineering designs, specifications, and construction methods to confirm they meet the project’s requirements. This often includes validating the work of the engineering, procurement, and construction (EPC) contractor.

Technical Review and Assurance

Review engineering designs, specifications, and construction methods to confirm they meet the project’s requirements. This often includes validating the work of the engineering, procurement, and construction (EPC) contractor.

Technical Review and Assurance

Review engineering designs, specifications, and construction methods to confirm they meet the project’s requirements. This often includes validating the work of the engineering, procurement, and construction (EPC) contractor.

Technical Review and Assurance

Review engineering designs, specifications, and construction methods to confirm they meet the project’s requirements. This often includes validating the work of the engineering, procurement, and construction (EPC) contractor.

Risk Management

Identifies and mitigates risks throughout the project lifecycle, ensuring that safety, environmental, and operational risks are adequately addressed.

Risk Management

Identifies and mitigates risks throughout the project lifecycle, ensuring that safety, environmental, and operational risks are adequately addressed.

Risk Management

Identifies and mitigates risks throughout the project lifecycle, ensuring that safety, environmental, and operational risks are adequately addressed.

Risk Management

Identifies and mitigates risks throughout the project lifecycle, ensuring that safety, environmental, and operational risks are adequately addressed.

Contractor Oversight

Monitors the performance of the EPC contractor, ensuring compliance with contractual obligations, quality standards, timelines, and budgets.

Contractor Oversight

Monitors the performance of the EPC contractor, ensuring compliance with contractual obligations, quality standards, timelines, and budgets.

Contractor Oversight

Monitors the performance of the EPC contractor, ensuring compliance with contractual obligations, quality standards, timelines, and budgets.

Contractor Oversight

Monitors the performance of the EPC contractor, ensuring compliance with contractual obligations, quality standards, timelines, and budgets.

Procurement Assistance

Supports the owner during the procurement process, such as tender preparation, bid evaluation, and vendor selection.

Procurement Assistance

Supports the owner during the procurement process, such as tender preparation, bid evaluation, and vendor selection.

Procurement Assistance

Supports the owner during the procurement process, such as tender preparation, bid evaluation, and vendor selection.

Procurement Assistance

Supports the owner during the procurement process, such as tender preparation, bid evaluation, and vendor selection.

Cost Control

Helps in evaluating costs and ensuring that the project remains within budget, providing cost-effective solutions without compromising quality.

Cost Control

Helps in evaluating costs and ensuring that the project remains within budget, providing cost-effective solutions without compromising quality.

Cost Control

Helps in evaluating costs and ensuring that the project remains within budget, providing cost-effective solutions without compromising quality.

Cost Control

Helps in evaluating costs and ensuring that the project remains within budget, providing cost-effective solutions without compromising quality.

Compliance with Regulations

Ensures that the project complies with all relevant codes, standards, and legal requirements.

Compliance with Regulations

Ensures that the project complies with all relevant codes, standards, and legal requirements.

Compliance with Regulations

Ensures that the project complies with all relevant codes, standards, and legal requirements.

Compliance with Regulations

Ensures that the project complies with all relevant codes, standards, and legal requirements.

Testing and Commissioning

Oversees or assists in the final testing and commissioning of the project to confirm it meets performance criteria before handing over for operation.

Testing and Commissioning

Oversees or assists in the final testing and commissioning of the project to confirm it meets performance criteria before handing over for operation.

Testing and Commissioning

Oversees or assists in the final testing and commissioning of the project to confirm it meets performance criteria before handing over for operation.

Testing and Commissioning

Oversees or assists in the final testing and commissioning of the project to confirm it meets performance criteria before handing over for operation.

Why Owners Engineering is Important:

Independence

Unlike contractors, the owner’s engineer works directly for the project owner, ensuring that decisions are made in the owner’s best interest.

Independence

Unlike contractors, the owner’s engineer works directly for the project owner, ensuring that decisions are made in the owner’s best interest.

Independence

Unlike contractors, the owner’s engineer works directly for the project owner, ensuring that decisions are made in the owner’s best interest.

Independence

Unlike contractors, the owner’s engineer works directly for the project owner, ensuring that decisions are made in the owner’s best interest.

Expertise

The owner may not always have the internal expertise required for large, complex projects, so owner’s engineering fills that gap.

Expertise

The owner may not always have the internal expertise required for large, complex projects, so owner’s engineering fills that gap.

Expertise

The owner may not always have the internal expertise required for large, complex projects, so owner’s engineering fills that gap.

Expertise

The owner may not always have the internal expertise required for large, complex projects, so owner’s engineering fills that gap.

Quality and Risk Control

Owner’s engineers help maintain project quality, ensure best practices are followed, and mitigate potential risks early in the project lifecycle.

Quality and Risk Control

Owner’s engineers help maintain project quality, ensure best practices are followed, and mitigate potential risks early in the project lifecycle.

Quality and Risk Control

Owner’s engineers help maintain project quality, ensure best practices are followed, and mitigate potential risks early in the project lifecycle.

Quality and Risk Control

Owner’s engineers help maintain project quality, ensure best practices are followed, and mitigate potential risks early in the project lifecycle.

Cost and Time Management

They help keep the project on time and within budget, balancing competing priorities between cost, quality, and schedule.

Cost and Time Management

They help keep the project on time and within budget, balancing competing priorities between cost, quality, and schedule.

Cost and Time Management

They help keep the project on time and within budget, balancing competing priorities between cost, quality, and schedule.

Cost and Time Management

They help keep the project on time and within budget, balancing competing priorities between cost, quality, and schedule.

Green Field Engineering

Onward Resources can support the planning, design, and construction of a completely new facility or project from scratch, on previously undeveloped land or a site that has no existing infrastructure. In contrast to brownfield projects, which involve modifying or expanding existing facilities, greenfield projects start with a blank slate, giving engineers more flexibility in design but often requiring significant groundwork and infrastructure development.

Onward Resources can support the planning, design, and construction of a completely new facility or project from scratch, on previously undeveloped land or a site that has no existing infrastructure. In contrast to brownfield projects, which involve modifying or expanding existing facilities, greenfield projects start with a blank slate, giving engineers more flexibility in design but often requiring significant groundwork and infrastructure development.

Characteristics of Greenfield Engineering in Oil and Gas:

New Site Development

The land or site has not been previously developed for oil and gas operations or any other industrial activity. This could be an entirely new oil field, refinery, processing plant, pipeline system, or other production facility.

New Site Development

The land or site has not been previously developed for oil and gas operations or any other industrial activity. This could be an entirely new oil field, refinery, processing plant, pipeline system, or other production facility.

New Site Development

The land or site has not been previously developed for oil and gas operations or any other industrial activity. This could be an entirely new oil field, refinery, processing plant, pipeline system, or other production facility.

New Site Development

The land or site has not been previously developed for oil and gas operations or any other industrial activity. This could be an entirely new oil field, refinery, processing plant, pipeline system, or other production facility.

Comprehensive Infrastructure Setup

Since the site is undeveloped, greenfield projects often require the establishment of all necessary infrastructure, including roads, utilities, pipelines, power systems, and possibly accommodation for workers.

Comprehensive Infrastructure Setup

Since the site is undeveloped, greenfield projects often require the establishment of all necessary infrastructure, including roads, utilities, pipelines, power systems, and possibly accommodation for workers.

Comprehensive Infrastructure Setup

Since the site is undeveloped, greenfield projects often require the establishment of all necessary infrastructure, including roads, utilities, pipelines, power systems, and possibly accommodation for workers.

Comprehensive Infrastructure Setup

Since the site is undeveloped, greenfield projects often require the establishment of all necessary infrastructure, including roads, utilities, pipelines, power systems, and possibly accommodation for workers.

Risk Management

Identifies and mitigates risks throughout the project lifecycle, ensuring that safety, environmental, and operational risks are adequately addressed.

Risk Management

Identifies and mitigates risks throughout the project lifecycle, ensuring that safety, environmental, and operational risks are adequately addressed.

Risk Management

Identifies and mitigates risks throughout the project lifecycle, ensuring that safety, environmental, and operational risks are adequately addressed.

Risk Management

Identifies and mitigates risks throughout the project lifecycle, ensuring that safety, environmental, and operational risks are adequately addressed.

Contractor Oversight

Monitors the performance of the EPC contractor, ensuring compliance with contractual obligations, quality standards, timelines, and budgets.

Contractor Oversight

Monitors the performance of the EPC contractor, ensuring compliance with contractual obligations, quality standards, timelines, and budgets.

Contractor Oversight

Monitors the performance of the EPC contractor, ensuring compliance with contractual obligations, quality standards, timelines, and budgets.

Contractor Oversight

Monitors the performance of the EPC contractor, ensuring compliance with contractual obligations, quality standards, timelines, and budgets.

Flexible Design Opportunities

Engineers have greater flexibility in planning and designing the layout of the facility since they are not constrained by existing structures or operational processes.

Flexible Design Opportunities

Engineers have greater flexibility in planning and designing the layout of the facility since they are not constrained by existing structures or operational processes.

Flexible Design Opportunities

Engineers have greater flexibility in planning and designing the layout of the facility since they are not constrained by existing structures or operational processes.

Flexible Design Opportunities

Engineers have greater flexibility in planning and designing the layout of the facility since they are not constrained by existing structures or operational processes.

Environmental Considerations

Greenfield projects often have more rigorous environmental impact assessments (EIAs), as the development could affect natural ecosystems, water sources, and wildlife. Engineers must factor in mitigation measures to minimize environmental damage.

Environmental Considerations

Greenfield projects often have more rigorous environmental impact assessments (EIAs), as the development could affect natural ecosystems, water sources, and wildlife. Engineers must factor in mitigation measures to minimize environmental damage.

Environmental Considerations

Greenfield projects often have more rigorous environmental impact assessments (EIAs), as the development could affect natural ecosystems, water sources, and wildlife. Engineers must factor in mitigation measures to minimize environmental damage.

Environmental Considerations

Greenfield projects often have more rigorous environmental impact assessments (EIAs), as the development could affect natural ecosystems, water sources, and wildlife. Engineers must factor in mitigation measures to minimize environmental damage.

Higher Capital Investment

These projects generally require a larger initial capital outlay compared to brownfield developments because everything needs to be built from the ground up—there are no pre-existing utilities, structures, or pipelines to leverage.

Higher Capital Investment

These projects generally require a larger initial capital outlay compared to brownfield developments because everything needs to be built from the ground up—there are no pre-existing utilities, structures, or pipelines to leverage.

Higher Capital Investment

These projects generally require a larger initial capital outlay compared to brownfield developments because everything needs to be built from the ground up—there are no pre-existing utilities, structures, or pipelines to leverage.

Higher Capital Investment

These projects generally require a larger initial capital outlay compared to brownfield developments because everything needs to be built from the ground up—there are no pre-existing utilities, structures, or pipelines to leverage.

Permitting and Regulatory Approvals

Greenfield projects usually face extensive regulatory scrutiny and require numerous permits for land use, construction, and environmental compliance, making the planning phase longer and more complex.

Permitting and Regulatory Approvals

Greenfield projects usually face extensive regulatory scrutiny and require numerous permits for land use, construction, and environmental compliance, making the planning phase longer and more complex.

Permitting and Regulatory Approvals

Greenfield projects usually face extensive regulatory scrutiny and require numerous permits for land use, construction, and environmental compliance, making the planning phase longer and more complex.

Permitting and Regulatory Approvals

Greenfield projects usually face extensive regulatory scrutiny and require numerous permits for land use, construction, and environmental compliance, making the planning phase longer and more complex.

Technology and Innovation

Since engineers have a clean slate, greenfield projects are often designed with the latest technologies and innovations, including more efficient production techniques, enhanced safety features, and advanced environmental management systems.

Technology and Innovation

Since engineers have a clean slate, greenfield projects are often designed with the latest technologies and innovations, including more efficient production techniques, enhanced safety features, and advanced environmental management systems.

Technology and Innovation

Since engineers have a clean slate, greenfield projects are often designed with the latest technologies and innovations, including more efficient production techniques, enhanced safety features, and advanced environmental management systems.

Technology and Innovation

Since engineers have a clean slate, greenfield projects are often designed with the latest technologies and innovations, including more efficient production techniques, enhanced safety features, and advanced environmental management systems.

Challenges in Greenfield Projects:

Cost:

The cost of developing an entirely new facility is often very high because of the need to build infrastructure and import equipment and materials.

Environmental Impact

Greenfield sites, particularly in sensitive ecosystems, may face opposition from environmental groups, local communities, and regulators.

Time to Completion

hese projects often take longer to complete due to the need for extensive groundwork and infrastructure, as well as the lengthy permitting process.

Logistical Complexity

Establishing supply chains and workforce accommodations in undeveloped areas can be difficult, particularly if the site is in a remote or challenging location.

Greenfield Engineering

Brownfield Engineering

Brown Field Engineering

NO PROJECT IS TOO SMALL. Onward Resources can support the modification, upgrade, expansion, or redevelopment of an existing facility or infrastructure. In contrast to greenfield projects, which are built from scratch on undeveloped land, brownfield projects involve working within the constraints of established assets, such as oil platforms, refineries, pipelines, or processing plants. These projects aim to enhance efficiency, increase capacity, extend the life of a facility, or adapt it to new technologies while minimizing downtime

NO PROJECT IS TOO SMALL. Onward Resources can support the modification, upgrade, expansion, or redevelopment of an existing facility or infrastructure. In contrast to greenfield projects, which are built from scratch on undeveloped land, brownfield projects involve working within the constraints of established assets, such as oil platforms, refineries, pipelines, or processing plants. These projects aim to enhance efficiency, increase capacity, extend the life of a facility, or adapt it to new technologies while minimizing downtime

Characteristics of Brown Field Engineering in Oil and Gas:

Characteristics of Brown Field Engineering in Oil and Gas:

Existing Infrastructure

Brownfield projects take place at sites where oil and gas operations are already present. This could be a mature oil field, an existing refinery, or an operating offshore platform. Engineers work within or alongside current infrastructure.

Existing Infrastructure

Brownfield projects take place at sites where oil and gas operations are already present. This could be a mature oil field, an existing refinery, or an operating offshore platform. Engineers work within or alongside current infrastructure.

Existing Infrastructure

Brownfield projects take place at sites where oil and gas operations are already present. This could be a mature oil field, an existing refinery, or an operating offshore platform. Engineers work within or alongside current infrastructure.

Existing Infrastructure

Brownfield projects take place at sites where oil and gas operations are already present. This could be a mature oil field, an existing refinery, or an operating offshore platform. Engineers work within or alongside current infrastructure.

Asset Optimization and Life Extension:

The primary goal of brownfield engineering is often to maximize the lifespan and performance of existing assets. This could include upgrading equipment, improving safety systems, retrofitting for environmental compliance, or debottlenecking processes to increase capacity.

Asset Optimization and Life Extension:

The primary goal of brownfield engineering is often to maximize the lifespan and performance of existing assets. This could include upgrading equipment, improving safety systems, retrofitting for environmental compliance, or debottlenecking processes to increase capacity.

Asset Optimization and Life Extension:

The primary goal of brownfield engineering is often to maximize the lifespan and performance of existing assets. This could include upgrading equipment, improving safety systems, retrofitting for environmental compliance, or debottlenecking processes to increase capacity.

Asset Optimization and Life Extension:

The primary goal of brownfield engineering is often to maximize the lifespan and performance of existing assets. This could include upgrading equipment, improving safety systems, retrofitting for environmental compliance, or debottlenecking processes to increase capacity.

Risk Management

Identifies and mitigates risks throughout the project lifecycle, ensuring that safety, environmental, and operational risks are adequately addressed.

Risk Management

Identifies and mitigates risks throughout the project lifecycle, ensuring that safety, environmental, and operational risks are adequately addressed.

Risk Management

Identifies and mitigates risks throughout the project lifecycle, ensuring that safety, environmental, and operational risks are adequately addressed.

Risk Management

Identifies and mitigates risks throughout the project lifecycle, ensuring that safety, environmental, and operational risks are adequately addressed.

Operational Constraints

Since brownfield projects are carried out at functioning facilities, engineers must plan around existing operations. This involves minimizing disruption to ongoing production and ensuring safety during construction or maintenance work. Shutdowns or turnarounds are often carefully timed and kept as short as possible.

Operational Constraints

Since brownfield projects are carried out at functioning facilities, engineers must plan around existing operations. This involves minimizing disruption to ongoing production and ensuring safety during construction or maintenance work. Shutdowns or turnarounds are often carefully timed and kept as short as possible.

Operational Constraints

Since brownfield projects are carried out at functioning facilities, engineers must plan around existing operations. This involves minimizing disruption to ongoing production and ensuring safety during construction or maintenance work. Shutdowns or turnarounds are often carefully timed and kept as short as possible.

Operational Constraints

Since brownfield projects are carried out at functioning facilities, engineers must plan around existing operations. This involves minimizing disruption to ongoing production and ensuring safety during construction or maintenance work. Shutdowns or turnarounds are often carefully timed and kept as short as possible.

Cost-Effective

Brownfield projects are generally less expensive than greenfield projects because they leverage existing infrastructure. However, costs can still be significant, especially when dealing with aging facilities that require substantial upgrades or retrofitting.

Cost-Effective

Brownfield projects are generally less expensive than greenfield projects because they leverage existing infrastructure. However, costs can still be significant, especially when dealing with aging facilities that require substantial upgrades or retrofitting.

Cost-Effective

Brownfield projects are generally less expensive than greenfield projects because they leverage existing infrastructure. However, costs can still be significant, especially when dealing with aging facilities that require substantial upgrades or retrofitting.

Cost-Effective

Brownfield projects are generally less expensive than greenfield projects because they leverage existing infrastructure. However, costs can still be significant, especially when dealing with aging facilities that require substantial upgrades or retrofitting.

Regulatory Compliance

Many brownfield projects are driven by the need to comply with new regulations or environmental standards. For example, retrofitting a refinery to meet stricter emissions guidelines or upgrading safety systems in an offshore platform to meet updated industry standards.

Regulatory Compliance

Many brownfield projects are driven by the need to comply with new regulations or environmental standards. For example, retrofitting a refinery to meet stricter emissions guidelines or upgrading safety systems in an offshore platform to meet updated industry standards.

Regulatory Compliance

Many brownfield projects are driven by the need to comply with new regulations or environmental standards. For example, retrofitting a refinery to meet stricter emissions guidelines or upgrading safety systems in an offshore platform to meet updated industry standards.

Regulatory Compliance

Many brownfield projects are driven by the need to comply with new regulations or environmental standards. For example, retrofitting a refinery to meet stricter emissions guidelines or upgrading safety systems in an offshore platform to meet updated industry standards.

Limited Design Flexibility

Unlike greenfield projects, brownfield engineering must accommodate the constraints of the existing facility, such as space limitations, legacy systems, and current operational processes. Engineers must design around these constraints, which can be challenging.

Limited Design Flexibility

Unlike greenfield projects, brownfield engineering must accommodate the constraints of the existing facility, such as space limitations, legacy systems, and current operational processes. Engineers must design around these constraints, which can be challenging.

Limited Design Flexibility

Unlike greenfield projects, brownfield engineering must accommodate the constraints of the existing facility, such as space limitations, legacy systems, and current operational processes. Engineers must design around these constraints, which can be challenging.

Limited Design Flexibility

Unlike greenfield projects, brownfield engineering must accommodate the constraints of the existing facility, such as space limitations, legacy systems, and current operational processes. Engineers must design around these constraints, which can be challenging.

Integration of New Technologies

Brownfield projects often involve integrating modern technologies into older facilities. This could include automation systems, digital monitoring, or new equipment that enhances efficiency and safety.

Integration of New Technologies

Brownfield projects often involve integrating modern technologies into older facilities. This could include automation systems, digital monitoring, or new equipment that enhances efficiency and safety.

Integration of New Technologies

Brownfield projects often involve integrating modern technologies into older facilities. This could include automation systems, digital monitoring, or new equipment that enhances efficiency and safety.

Integration of New Technologies

Brownfield projects often involve integrating modern technologies into older facilities. This could include automation systems, digital monitoring, or new equipment that enhances efficiency and safety.

Challenges of Brownfield Projects:

Challenges of Brownfield Projects:

Operational Risks

Working on an operational site requires careful coordination to ensure that production is not disrupted and that safety risks are minimized. Shutdowns may be required for certain upgrades, impacting overall production.

Aging Infrastructure

Dealing with older equipment and systems can be complex, as outdated components may need to be replaced or upgraded. Maintenance and structural integrity issues may also arise during the project.

Space and Layout Constraints:

Existing facilities may have limited space for expansion or upgrades, requiring creative engineering solutions to work within these physical limitations.

Environmental and Safety Concerns

Upgrading facilities often involves complying with modern environmental standards and safety regulations, which can require significant modifications to the site’s infrastructure.

Advantages of Brownfield Projects

Advantages of Brownfield Projects

Lower Capital Investment

Since existing infrastructure is utilized, the capital costs are typically lower than in greenfield projects.

Faster Implementation

Brownfield projects generally have shorter timelines compared to greenfield projects, as there is no need for extensive site preparation or infrastructure development.

Reduced Environmental Impact

Brownfield developments may have less environmental impact since the site is already developed, reducing the footprint of new construction and minimizing the need for land clearance.

Ready to get started with your next project?

Ready to get started with your next project?

Ready to get started with your next project?

Ready to get started with your next project?